Given the development of industry standards globally, Load Sensing Systems (LSS) are now required on all mobile elevating work platforms (MEWP), which stipulates that the MEWP includes platform monitoring tools. This has challenged MEWP manufacturers to adopt, implement and develop new technologies to help equipment operators determine if the platform has been overloaded beyond the safe limits of the machine.

Sometimes, a MEWP (formerly known as aerial work platform) can be overloaded due to too much weight on the platform, weight to the platform when it is raised, sensor failure, lifting onto overhead structures or falling debris onto the platform elevated.

There are many approaches to determining platform load. Especially for scissor lifts, overload conditions result in all vehicle movement being unable to move until the excessive weight of the platform is removed. The pressure-based load sensing system for scissor lifts is used as a safety regulation system. It is designed to monitor the platform's loads, materials and equipment, ensuring the vehicle's capacity rating is not exceeded. In addition to the basic requirements mentioned above, the system has other functional, calibration and diagnostic requirements to ensure operator safety.

Uses of Load Sensing System

For Scissor Lifts, the Load Sensing System (LSS) is designed to monitor the forces acting on the main lift cylinder, as well as the height of the platform. To determine the platform load, the sensor data, such as elevation and cylinder pressure, will be measured against the data recorded in the calibration process. Then the scissor lift will determine whether the load is greater than the maximum operating capacity allowed by the machine when operating indoors or outdoors.

In case of overload, the system will require the operator to sound a sequence of alarms and indicator lights on the platform and ground control. The scissor lift then disables all drive and steering functions and prevents further elevation until the overload state disappears. A manual lowering system or ground control station can also be used in an emergency to save the operator.

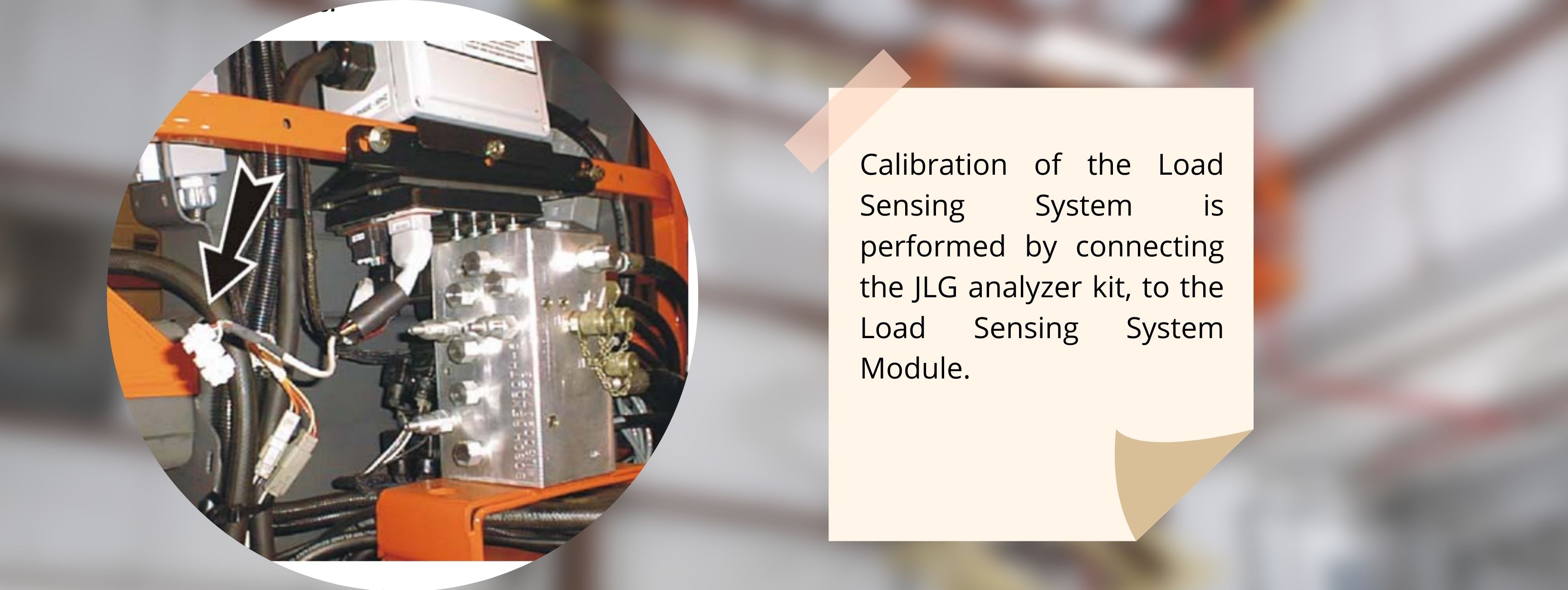

Calibration

Due to wear or component failure, Scissor Lifts with a load sensing system (LSS) require periodic recalibration. When a routine service is performed, and sensors fail, or the machine fails to pass the annual inspection, the technician must perform an LSS calibration so the system can learn about the machine's new mechanical characteristics.

During calibration, most scissor lifts will require the operator to load the platform with a load up to the maximum capacity of the platform. The control system then uses the pressure and elevation to generate a dynamic pressure calibration curve that can be used to determine if an overload condition exists.

Diagnostic

In an overload situation, to eliminate the overload condition and resume normal operation, the operator must remove the load from the platform until the overload condition is no longer present, or the technician may have to repair the machine. Visual platform and ground indicators will be displayed when overload is active other than when the platform is no longer over capacity.

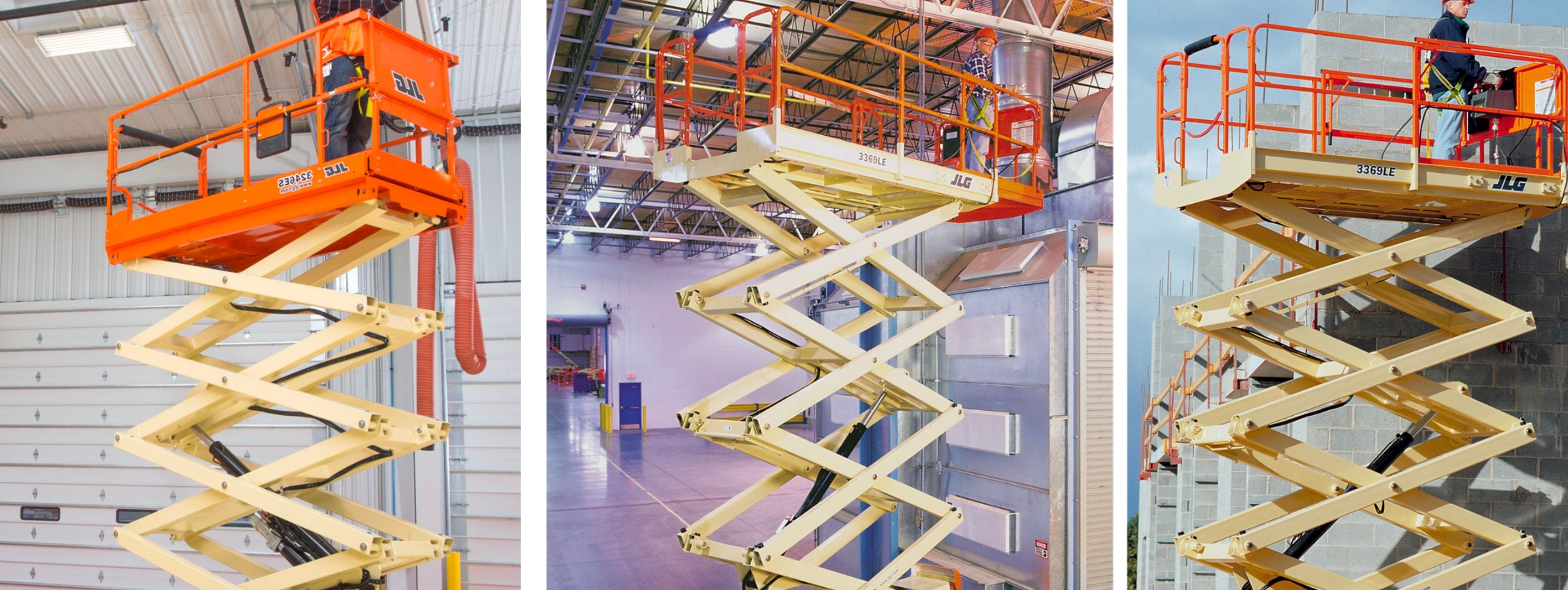

JLG's Scissor Lift Load Sensing System

The current load sensing system for the JLG Scissor Lift takes lessons from the previous system and improves machine calibration and functional and diagnostic performance. Currently, JLG uses pressure transducers on the rod side of the lift cylinder and the cylinder head side to compensate for the viscosity of the hydraulic fluid at low temperatures. The hydraulic cylinder also contains oil inside the rod side of the barrel to lubricate the cylinder seals, reducing wear. As the cylinder rod lengthens, this fluid is transferred back to the main reservoir. When lifting down, the system diverts the trapped liquid on the barrel side of the cylinder through the remaining rod side cavities inside. Any excess fluid exits through the stem cavity and returns to the reservoir. The weight of the platform provides the force needed to retract the cylinder.

The advantage of JLG's Load Sensing System (LSS) is that it allows the operator to lift overloaded to a certain distance; however, when the overload light is on, it will not prevent the operator from descending.

Traktor Nusantara also provides various heavy equipment for your needs, one of which is the JLG Scissor Lift. For more information about the JLG Scissor Lift, don't hesitate to contact TRAKNUS Contact Center at 1500-072 or Whatsapp in 0815-1106-1974. (PAS)

Source : jlg.com

When working at heights, boom lifts are the right machinery to use. Th...

Read More

Currently, companies must carry out the production, logistics, and dis...

Read More

Forklifts are useful for transporting goods in factories, warehouses,...

Read More

UPS (Uninterruptible Power Supply) is essential equipment to support c...

Read More